Reduce Haul Truck Fuel Consumption

A MineCare customer shares how minor modifications to operator behavior during the dumping cycle can generate significant fuel savings.

LOCATION

Brazil

OBJECTIVE

To reduce haul truck fuel consumption

RESULTS

82,795 L annual fuel savings by eliminating excessive engine throttle during dumping

Challenge

Today’s mining haul trucks consume huge volumes of fuel as they move hundreds of thousands of tons around the clock. Mine managers are always looking for ways to reduce this considerable operating cost. In this case study, we’ll explore how a Modular customer identified a potential opportunity to save fuel during the dumping cycle. They were surprised to find that a simple change in operator behavior could result in significant annual fuel savings.

Solution

With a fleet of 72 240-ton haul trucks, the mine knew they had a huge opportunity to save fuel. Modular engineers selected a control group of roughly 1/3 of the fleet, and installed a set of MineCare trends to capture fuel consumption and engine speed while dumping. Using DISPATCH production data, results were extrapolated to reveal a substantial cost saving opportunity.

“The MineCare system enabled us to improve more than just equipment reliability, identifying and correcting operator behavior that wastes fuel.”

— Corporate Reliability Advisor

Data Capture & Analysis

When the customer asked for an explanation behind spikes in fuel consumption during dumping, Modular Engineers went to site to capture data. Using the MineCare trending application, they set up triggers to collect both engine speed and fuel consumption for each of the following scenarios:

- Scenario 1: Engine Speed >1500 RPM, bed up (dumping)

- Scenario 2: Engine Speed >1900 RPM, bed up (dumping)

For a one-month period, events were recorded when a trigger indicated a load was being dumped with engine speed in excess of 1900 RPM.

Using the DISPATCH system, the weekly load average for the 26 truck control was calculated to be 5763. Compared to the average weekly alarms of 1728, this produced a probability of 30% that a given dumping cycle exhibited excessive engine speed.

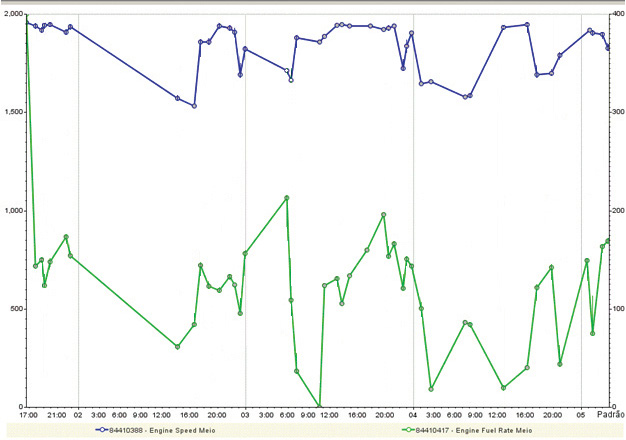

Figure 1: A MineCare trend graph shows the relationship between engine speed (blue) and fuel consumption rate (green).

| DATE RANGE | # ALARMS (EXCESSIVE RPM WITH BODY UP) | % TRUCKS AFFECTED |

|---|---|---|

| 03 - 09 May | 1,564 | 27.14 |

| 10 - 16 May | 1,928 | 33.45 |

| 17 - 23 May | 527 | 9.14 |

| 24 - 30 May | 2,289 | 39.72 |

| 31 May - 06 June | 2,334 | 40.50 |

| Avg # Alarms per Week | 1,728 | 29.99% |

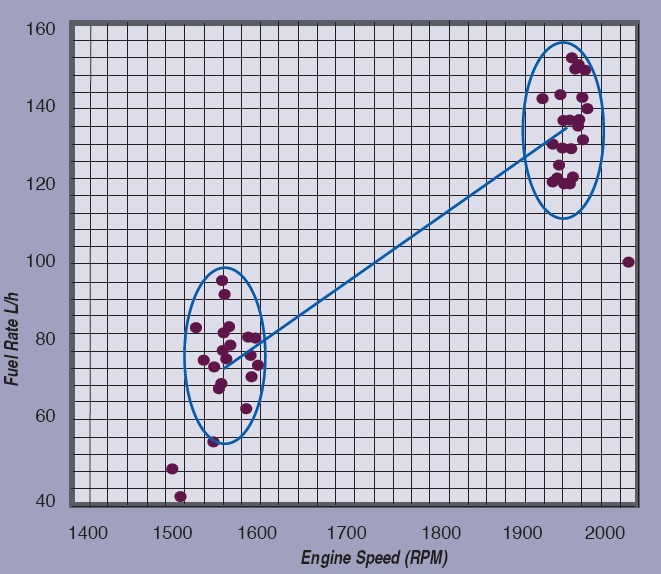

Using empirical analysis, it was discovered that average fuel consumption rate nearly doubles when engine speed increases from 1500 to 1900 RPM.

Figure 3: Notable increase in fuel consumption rate between 1500 and 1900 RPM

| Normal Idling Engine Speed | Excessive Engine Speed | |||

|---|---|---|---|---|

| RPM | L/h | RPM | L/h | |

| Truck 1 | 1.557 | 69,45 | 1.918 | 128,68 |

| 1.592 | 81,55 | 1.913 | 120,96 | |

| 1.590 | 71,92 | 1.915 | 124,57 | |

| Truck 2 | 1.559 | 70,35 | 1.908 | 129,65 |

| 1.590 | 77,32 | 1.915 | 141,81 | |

| 1.598 | 75,03 | 1.909 | 120,38 | |

| Truck 3 | 1.562 | 92,62 | 1.935 | 148,96 |

| 1.585 | 63,97 | 1.934 | 133,84 | |

| 1.566 | 84,06 | 1.940 | 130,51 | |

| Truck 4 | 1.559 | 95,72 | 1,920 | 135,40 |

| 1.541 | 76,18 | 1.928 | 121,28 | |

| 1.531 | 84,07 | 1.942 | 147,81 | |

| Truck 5 | 1.551 | 56,07 | 1.897 | 140,76 |

| 1.561 | 83,01 | 1.921 | 119,72 | |

| 1.560 | 78,66 | 1.939 | 141,06 | |

| Truck 6 | 1.506 | 49,24 | 1.936 | 135,41 |

| 1.515 | 42,50 | 1.945 | 137,86 | |

| 1.568 | 79,96 | 1.925 | 135,26 | |

| Truck 7 | 1.586 | 81,75 | 1.929 | 150,99 |

| 1.564 | 76,54 | 1.926 | 128,71 | |

| 1.551 | 74,59 | 1.933 | 148,43 | |

| Average | 1,526 RPM = 74.50 L/h | 1,925 RPM = 134.88 L/h | ||

Figure 4: Average fuel consumption rate nearly doubles when engine speed jumps from 1500 RPM to 1900 RPM

Theoretical Fuel Savings Estimation

The engineering team calculated that the dump time per truck averaged 20 seconds based on historical performance data gathered from the DISPATCH system. The data showed that dumping time was not affected by engine speed, i.e. operators pushing the accelerator pedal while dumping did not raise the bed any faster than those that didn’t. However, this behavior did consume 80% more fuel.

Combining data gathered from both systems, a theoretical maximum annual fuel savings was calculated on a per truck basis. The total cost savings associated with solving excessive engine RPM during dumping can be extrapolated to the entire truck fleet using the annual cost savings/truck across a range of 30% to 100% of total loads. This provides an expected minimum savings based on the 26 truck control group, but also a potential maximum savings assuming all truck operators exhibit the behavior.

At 30% of the total loads, the 72 truck fleet fuel savings can be estimated at 83,000 L per year. However, the total potential cost savings at 100% of loads is over 275,000 L per year. This scenario would save 736 metric tons of CO2 from being released into the atmosphere—the amount it would take 157 acres of pine or fir forests to annually sequester, or equivalent to recycling 247 metric tons of waste every year.

| Actual Sample (30% of Loads) | Theoretical Worst Case (100% of Loads) | Best Practice (0% of Loads) | |

|---|---|---|---|

| Average Dump Time | 20 seconds | 20 seconds | 20 seconds |

| Average Fuel Rate | 92.46 L/hr | 134.38 L/hr | 74.5 L/hr |

| Avg. Fuel (consumed while dumping) | .514 L | .747 L | .414 L |

| Average Laods/week | 222/hr | 222 | 222 |

| Total Fuel Consumed While Dumping per Year | 5,933.6 L | 8,623.4 L | 4,779.2 L |

Maximum Annual Fuel Savings per Truck:

3,844.2 L

Conclusion

POTENTIAL COST AVOIDED:

$335,000

Assuming an average fuel price of US$1.21/L, the expected range of savings for this customer is between $100,000 and $335,000 per year. This demonstrates that a relatively simple exercise in researching operator behavior can translate to real and substantial annual cost savings, and shows that the MineCare system can be used to alter operator behavior, directly impacting operating costs.