Go beyond technology. Get Results.

Leverage Modular Mining’s full solutions suite to truly maximize your value, sustain your improvements, and grow over time. Each system and service builds upon another, providing more value and process improvements than you can derive from just a singular technology.

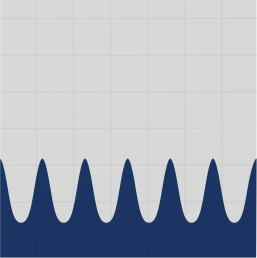

Without Modular Mining Solutions

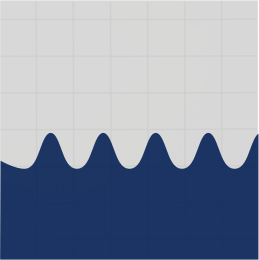

With Deployment Services

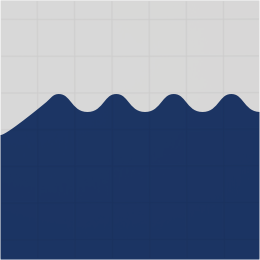

With Customer Care Package

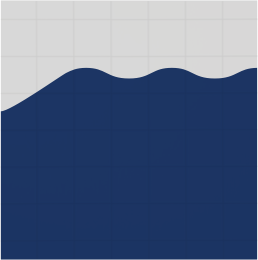

With Value-add Services

5+% Productivity Increase

Location: Brazil

By:

- Conducting haulage simulations

- Deploying the DISPATCH FMS as a replacement for their previous system

- “Unlocking” equipment assignments

- Providing thorough on-site training for mine personnel via Assisted Operations

17% Increase in Production

Location: Africa

By:

- Reconfiguring crusher feed rates

- Configuring truck-shovel matching

- Providing dispatcher training to correctly handle exceptions

- Providing hands-on training for crusher operators via Assisted Operations

30% Productivity Improvement

Location: Africa

By:

- Ensuring compliance to the short-term mine plan

- Providing hands-on dispatcher training via Assisted Operations

- Ensuring organization-wide technology adoption

- Improving current processes and procedures

- Establishing best practices to continue driving improvements

Deployment and Installation

OUR COMMITMENT

Establish mutually agreed-upon KPI’s and deliver that promised value prior to leaving your site

We install every IntelliMine technology in person, with a highly specialized and very professional team. But to us, a system deployment is so much more than just installing some hardware and software and connecting cables.

At Modular Mining, every one of our system deployments requires that we achieve a mutually agreed-upon value or specific improvement before we leave your site.

After demonstrating that value, we stay on site to ensure that your team can continue to drive that value on their own, even after we leave.

“By engaging with our customers and working with them side-by-side at the mines, we can better tailor our solutions to their needs and ensure that they achieve clear and measurable results.”

– Jorge Mascena, CEO, Modular Mining

HOW WE DO IT

On-time, on-budget, and on-site deployments to:

Maximize your System Availability

We'll evaluate your network capacity, GPS availability, and other requirements to ensure continuous system availability

Increase Your Technology Potential

We'll calibrate and configure all system settings to suit your specific mine's needs

Thoroughly train operators and dispatchers

We'll ensure understanding of system functionality and increase operator buy-in of technology

Customer Care Program

OUR COMMITMENT

To help you unlock the potential of your Modular Mining technology over the life of your investment

24/7 SUPPORT

Should you have general product questions, need troubleshooting help, or seek emergency assistance, we’re here to help, 24 hours a day, 7 days a week, 365 days a year.

For me, the biggest strength that Modular has is in the support, the customer support we have. The around the clock, 24-hour support.”

– IntelliMine Customer, South Africa

Local Modular Mining Office

Get general product advice and answers to routine questions. Available Monday-Friday during normal business hours.

Click here to see all of our regional locations.

On-Site Support

Schedule a support visit with a skilled harware or software technician (for issues requiring hands-on attention)

Contact your Modular account representative to schedule a visit.

Emergency Support

If a critical issue or system failure arises, emergency phone support is available 24/7/365

+1 (520) 629-1614Maximize your System Availability

Our IntelliMine solutions, system firmware, and reporting tools are kept current through timely distribution of defect fixes, software patches, and maintenance releases

Go to my customer portalContinuity and Compatibility Guarantee

Participation in the Customer Care Program ensures compatibility between your current- and last-generation Modular Mining hardware and software.

Contact your Modular account representative for more information.

PERFORMANCE ASSURANCE

During each engagement, a dedicated Performance Assurance team collaborates with your mine personnel across multiple levels to develop tailored, flexible, and proactive solutions.

Working together, we establish mutually-defined goals and milestones, and create and track quantifiable key performance indicators (KPIs).

Participating mines have seen numerous benefits, including:

- Enhanced truck productivity

- Reduced truck queue times

- Improved net production through shorter shift change duration

- Lowered equipment maintenance costs

“In the Performance Assurance area, they send a wide variety of professionals to the site to help with different problems we are having. We have gotten solutions to some issues that we have had and it has really been a good gain for us.”

– IntelliMine Customer, South Africa

SEE THE CASE STUDIES

ADDITIONAL BENEFITS

Return Merchandise Aurthorization (RMA)

Ensure ongoing capacity assurance by reporting problems or failures with your Modular Mining hardware in a timely manner.

Should it be necessary, we will replace or repair your hardware or components, in a five day turnaround.

Preferred Pricing and Purchase Discounts

As a participant in the Customer Care Program, you may be eligible for reduced standard pricing on Modular products and services.

You may also receive discounts based on your purchase of additional support options.

HOW WE DO IT

On-Site visits are vital to helping you succeed. We will work with your mine personnel at multiple levels to establish:

Solutions

We'll develop tailored, flexible, and proactive solutions

Goals

We'll establish mutually-agreeable goals and milestones

KPIs

We'll create and track quantifiable key performance indicators

Value-add Services

Mine Plan Compliance

OBJECTIVE:

Reduce your operational costs by closing the gap between your mine plan and execution

The Mine Plan Compliance Program, our technology-based consulting approach, helps mines create synergy among departments, processes, and systems, thus increasing your ability to consistently execute according to plan.

Mine Plan Compliance also helps mines facilitate the cultural shift needed to help personnel accept and internalize changes to operating procedures and best practices, ultimately leading to demonstrable improvements in efficiency, performance, and process control.

“It has really helped us find the opportunities to increase overall mine performance – certainly value added. It has added value to our operation.”

– IntelliMine Customer, South Africa

HOW WE DO IT

Longer-term on-site visits that empower you to leverage our:

Deep Understanding...

...of the mining process and your mine planning expectations and needs

Ability to think beyond our technological solutions...

...to solve your challenges

Thoroughly training for operators and dispatchers...

...performed by mining professionals and senior product specialists

Collaboration...

...with your mine personnel at various levels

RemoteCare Off-site Monitoring

OBJECTIVE:

Reduce your maintenance costs, increase your equipment uptime, and improve your maintenance approach

“Thanks to RemoteCare’s proactive management of critical alerts, we have been able to optimize monitoring for our entire truck fleet, both Komatsu and CAT, by providing the right information to the right people 24 hours a day.”

– RemoteCare customer in South America

Related Case Study:

Working from our geographically-distributed Centers of Excellence, teams of specialists remotely monitor and manage the real-time telemetry data generated by your mobile equipment fleet.

Leveraging the widest array of original equipment manufacturer (OEM) interfaces on the market, we’ll relay machine health information to identify possible problem areas in advance, and provide directed feedback and recommendations to your maintenance and operations personnel to address potential component breakdowns before they become catastrophic failures.

HOW WE DO IT

Establish and remotely monitor user-defined and OEM event triggers from your entire fleet to:

Reduce unscheduled downtime

We'll increase your equipment reliability by monitoring component condition to identify potential issues early and schedule their repair or replacement

Maximize equipment and labor utilization

We'll help you establish a more predictive maintenance approach to minimize upset events

Thoroughly train operators and dispatchers

We'll identify additional opportunities for improvement

Identify best practices at benchmark sites

We'll leverage the success from benchmark sites to apply similar best practices throughout your enterprise