Active payload management helps African gold mine realize an expected $49M in additional annual revenue

Payload management and reporting accuracy can prove challenging on mine sites. Many sites still determine their payload volumes manually, often considering a truck’s total capacity for each load rather than the actual payload volume. The challenge is further complicated by differences in OEMs; some OEMs include payload counters in their truck beds, while others don’t.

By implementing a payload management system, like the optional Payload module from the DISPATCH® FMS, mines can tighten their payload distributions to significantly improve payload management, reporting, and overall site production.

LOCATION

Republic of Guinea, West Africa

GOAL

Increase payload accuracy and overall production

RESULTS

46% increase in ore production, representing US$49M in expected annual revenue

Challenge

After several years of feed grade reductions and increases in cash costs, the mine reached out to Modular Mining’s Performance Assurance (PA) team to help optimize their truck loading efficiencies and improve productivity. Prior to Modular Mining’s involvement, the mine managed their payload manually throughout each shift cycle, which created issues around data accuracy and consistency.

During Modular Mining’s on-site visit, the PA team compared the surveyed payload volume to the actual production volume reported by the DISPATCH FMS, which varied significantly. As a result, the site’s trucks were being underloaded by an average of 20%, limiting the operation’s productivity.

Furthermore, the manual payload process made it difficult for the mine to proactively monitor and manage their payload efficiencies.

Solution

Since the mine already leveraged the DISPATCH FMS to manage its equipment assignments in real time, the PA team suggested implementing the DISPATCH system’s optional Payload Management (PLM) module, which captures real-time payload information from the VIMS systems on the mine’s fleet of Caterpillar trucks.

The module transmits the payload data to loading equipment operators in real time, increasing their visibility and awareness of their actual payload volume. It also facilitates storage of all collected payload data for detailed analysis and reporting.

The PA group worked directly with the mine’s leadership and technical team, as well as OEM support personnel, to collect data that would help improve calibration and identify potential equipment issues, before implementing the PLM module across their truck fleet.

After enabling the module, the PA team tracked the mine’s payload for a month to generate a baseline.

Using the data from the VIMS interface, they then worked with the mine’s Business Improvement team to develop operator scorecards for each operator to track their own loading efficiency. The scorecards are also helpful in understanding specific operator performance and identifying training opportunities for operators who need it.

Bi-weekly review meetings with key stakeholders helped continually improve system calibration, while also highlighting loading efficiency improvements.

Results

By the end of the 6-month period, the variance between the mine’s target and actual payloads had improved significantly.

After implementation, the mine has:

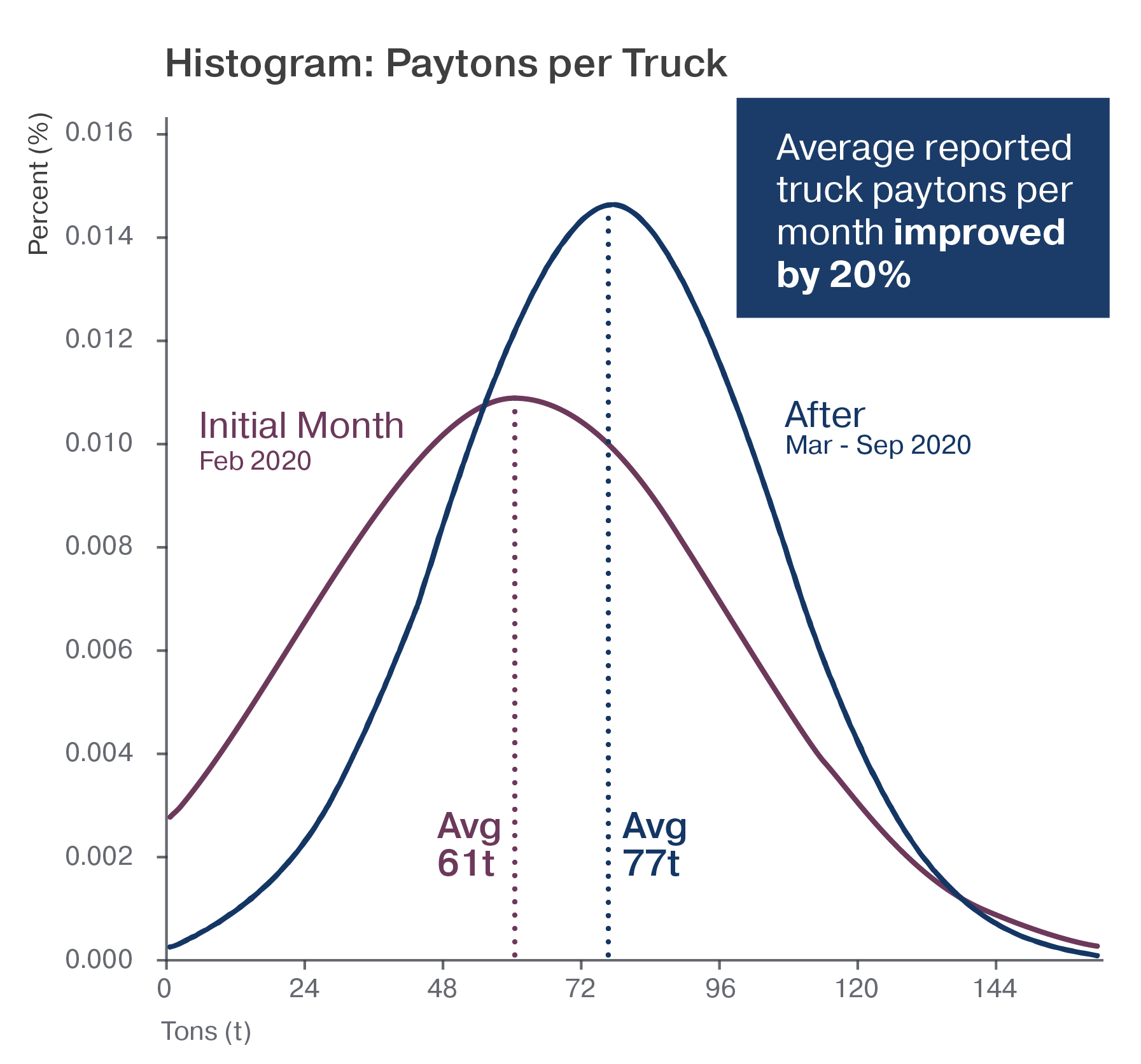

- Increased truck loading efficiencies by 20%, from an average of 61t per truck to an average of 77t per truck (figure 1)

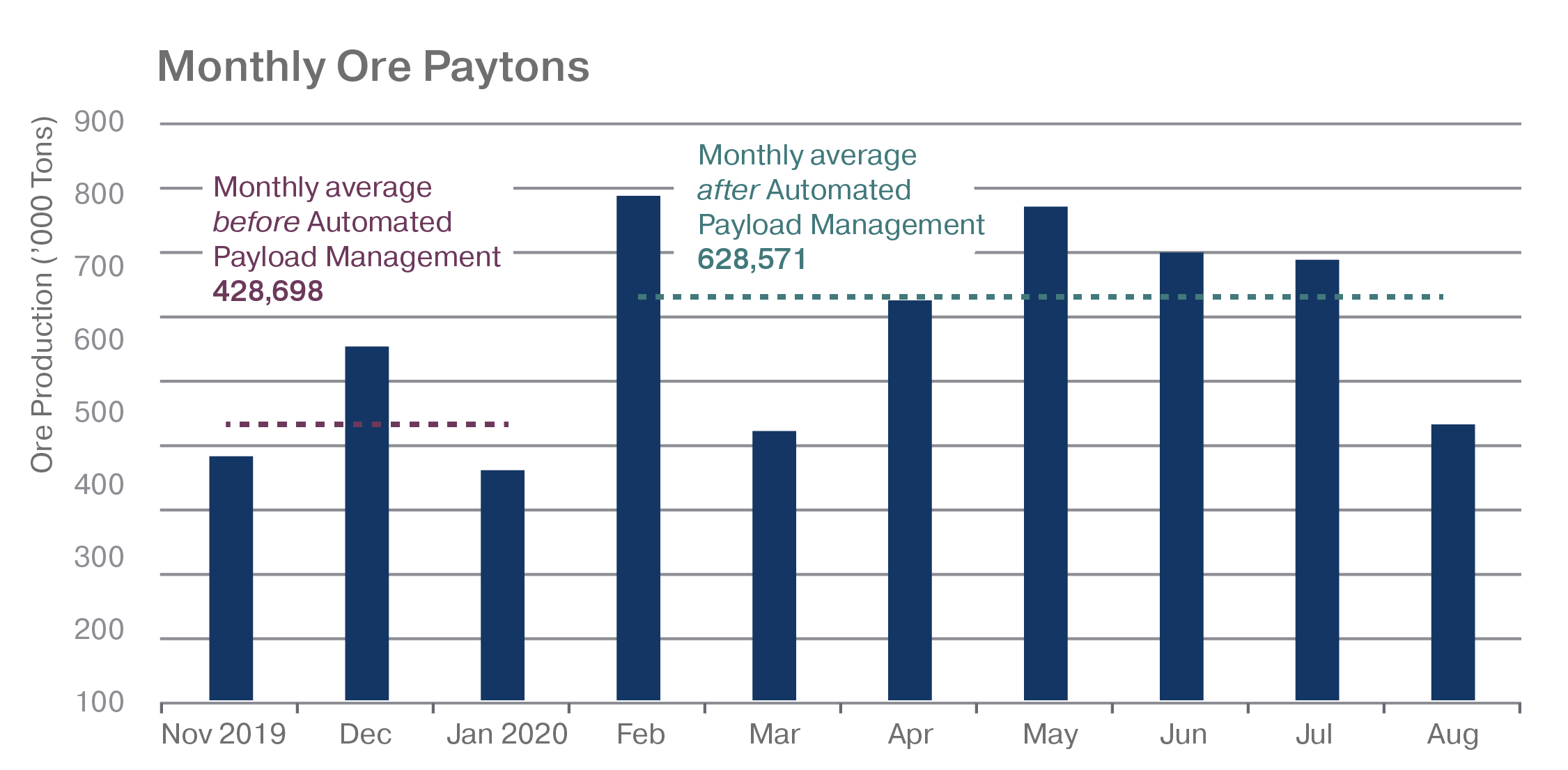

- Increased monthly ore production throughput by 46%, or approximately 199kT, representing a potential annual increase of roughly US$49M, based on a commodity price of US$1,887.90 per oz (figure 2)

Figure 1. After implementing the DISPATCH PLM module, the mine has seen a 20% increase in loading accuracy.

Figure 2. Monthly ore production improved by nearly 46% after implementing the DISPATCH Payload module.

Conclusion

Through collaboration with Modular Mining’s PA team, site leadership, the mine’s corporate Business Improvement team, and OEM support personnel, the mine’s total production has improved significantly. Their payload distribution is now much tighter than when they manually calculated it, which will allow the mine to target a more aggressive payload without risk of overloading their trucks.

By replacing their manual, inaccurate payload tracking process with the DISPATCH system’s automated calculations, the mine dramatically improved their operator practices and overall production; they will also benefit from simplified reporting and can now start proactively monitoring and managing their payload efforts.