Modular Mining helps iron ore mine increase productivity through improved utilization of DISPATCH system optimization

Modular Mining takes a holistic approach to customer satisfaction. This multi-faceted strategy begins with gaining a thorough understanding of each customer’s challenges, requirements, and goals. The acquired knowledge then guides the deployment, implementation, and ongoing support of the installed technologies at the customer’s site.

LOCATION

Large iron ore mine in Brazil

OBJECTIVE

Improve productivity, increase production

OUTCOME

Productivity increase of more than 5%

Challenge

During an engagement with a large iron ore operation in Brazil, early pre-sales conversations between Modular and mine personnel revealed that the mine’s primary objective was to improve the productivity of their existing haulage fleet.

In response, Modular Mining conducted a sequence of haulage simulations to estimate the productivity gains the mine could potentially achieve by implementing the DISPATCH® Fleet Management System (FMS).

Productivity Gains: Validation Process

At the completion of the testing phase, Modular Mining performed a post-deployment assessment to validate the measurable improvements that were delivered. In doing so, Modular Mining’s Product Deployment and Performance Assurance (PA) teams worked closely with the customer to ensure that the mine’s performance met expectations.

Modular Mining and mine personnel agreed to use Equivalent Tonne Kilometer per Hour (ETKPH) to compare productivity

among discrete time periods, mine layouts (grade and distances), and fleets. ETKPH provides a normalized comparison of haul distance by accounting for the grade of the haul road. For example, steep uphill road segments have a longer “equivalent haul” than a flat or downhill road segment of the same length. Using this information, Modular Mining monitored the mine’s performance for three weeks, with each week correlated to a phase, as described in the sections that follow.

Monitoring Period

Phase 1 (Baseline)

- All equipment units operated in locked (non-optimized) mode to emulate the functionality found in most fleet management systems on the market

- Reassignment beacons and optimization parameters were disabled

- Dispatchers’ FMS interactions limited to processing exceptions (Accept or Reject)

Phase 2

- All equipment units operated in unlocked (optimized) mode to utilize the DISPATCH FMS’ optimization functionality

- Modular Mining provided Assisted Operation

- Reassignment beacons and optimization parameters were enabled

- Dispatchers’ FMS interactions included processing exceptions (Accept or Reject), changing parameters such as shovel priority and crusher feed rate, and stopping trucks in overtrucking situations

Phase 3

- All equipment operated in unlocked mode

- Reassignment beacons and optimization parameters were enabled

- Dispatchers’ FMS interactions included processing exceptions (Accept or Reject), changing parameters such as shovel priority and crusher feed rate, and stopping trucks in overtrucking situations

The DISPATCH FMS Advantage

Optimized truck assignments are continuously calculated and are automatically sent to truck operators in real time.

The DISPATCH FMS simultaneously considers many haulage fleet operating characteristics, such as desired feed rates, travel time, equipment status, shovel-to-truck matching, region/shovel locks and material/shovel/dump bars, to revise truck assignments during a shift. This mode of operation is commonly referred to as “running unlocked.”

In contrast, in systems without optimization capability, trucks are often allocated to specific shovels and dumps at the start of a shift and are rarely updated until the next shift change. Dispatchers may not be aware of changes in haul route conditions, equipment availability, or other factors affecting the viability of these assignments throughout the shift. This mode of operation is commonly referred to as “running locked.”

Results

Phase 1 (Baseline)

Modular Mining established the baseline for comparison. During this phase, the mine continued to run the FMS in locked mode, with dispatchers manually assigning trucks to shovels for loading.

Phase 2

The mine increased its use of small shovels and decreased its use of large shovels, resulting in longer loading times. Because of this unanticipated change in fleet utilization, productivity in Phase 2 improved by 2.4%; however, Modular Mining and mine personnel’s expectations remained high that additional gains were possible.

Phase 3

With guidance from the Performance Assurance team, the dispatchers applied their increased system knowledge and the mine operated the FMS unlocked almost exclusively. As a result, productivity increased by more than 5%.

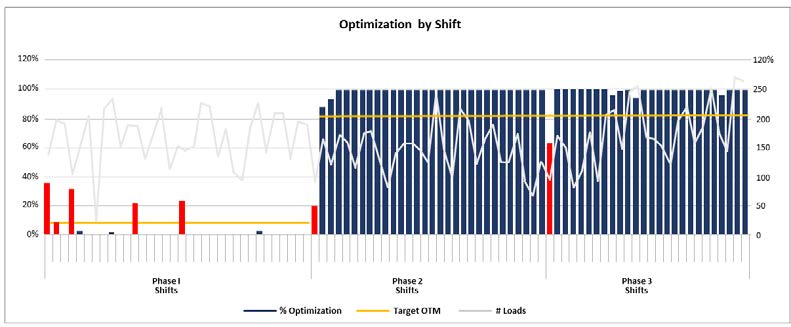

The improvements in ETKPH by phase, and the effects of DISPATCH FMS optimization by shift, are shown in Figures 1 and 2.

Conclusion

At the end of the three-phase monitoring period, the mine understood the importance of proper FMS configuration. They also realized the positive effects that running unlocked could have on both short- and long-term efficiency, productivity, and performance.

Through the collaborative, integrated efforts of Modular Mining’s Business Development, Project Deployment, and Performance Assurance groups, the mine had real-world proof that use of DISPATCH FMS optimization could lead to substantial productivity improvements. The mine has also used the results to justify DISPATCH system investment at other affiliated sites.

Based on the positive simulation results, the mine decided to replace its existing FMS with the DISPATCH system. The same results were used to establish clear performance targets for the Modular Mining Project Deployment team during project implementation and validation.