Modular Mining’s Performance Assurance Team helps Bear Run Mine increase night shift production by nearly 8%

Challenge

Fleet management systems (FMSs) are deployed at the majority of open-pit mines, where the systems provide numerous operational efficiencies and productivity gains. However, not all mines utilize the technology to its full potential, thus leaving value, behind. This was the case for the night-shift operations at Peabody Energy’s Bear Run open-pit coal mine in Sullivan County, Indiana, USA.

LOCATION

Indiana, USA

GOAL

Improve night shift production

RESULTS

Nearly 8% production increase and improved truck availability

Background

On the day shift, Bear Run’s dispatchers took full advantage of the DISPATCH FMS functionality. Their utilization of the system’s capabilities, including automated truck-shovel pairing, real-time dynamic assignment changes and haulage optimization, was evidenced by the day shift’s consistently-high performance. In contrast, despite having the same access to the DISPATCH system as the day-shift, night shift performance was routinely low; a concern that mine personnel brought to the attention of the PA team.

As part of an onsite engagement, the PA team observed the mine’s operating practices for five nights and collected production data for analysis. The PA team learned that the night shift dispatch crew had a high percentage of new-hires. Limited experience with the DISPATCH system and a lack of understanding of the FMS’ ability to control the fleet, led the dispatchers to specify which shovel each truck would (or would not) use for loading. Because these methods, known as locking and barring, do not consider changes in pit conditions or equipment status when making assignments, they often lead to decreased performance and lower production totals. In contrast, running the DISAPTCH system unlocked, as done during the day shift, takes full advantage of the FMS’ dynamic fleet optimization capabilities for increased productivity and efficiency.

Resolution

PA team members worked alongside Bear Run’s night-shift dispatchers to explain the importance of key FMS functions and show the dispatchers how correct FMS utilization would have a positive impact on performance. The PA team also conducted targeted coaching and mentoring sessions to reinforce how the accuracy of the FMS’ haulage route map affected the system’s ability to optimize truck assignments for maximum efficiency. A site-specific Dispatcher Daily Checklist was also provided to help the dispatchers manage system configuration and parameters.

“The Performance Assurance Team from Modular Mining and the Fleet Management Team at Bear Run; working together through planning, weekly follow-up and quarterly site visit execution, have improved optimization practices by the Dispatchers,” said Griffith. “Every cycle visit, we look forward to the continuous improvement we are experiencing, together.”

– Eric Griffith, Lead Dispatcher at Bear Run

Results

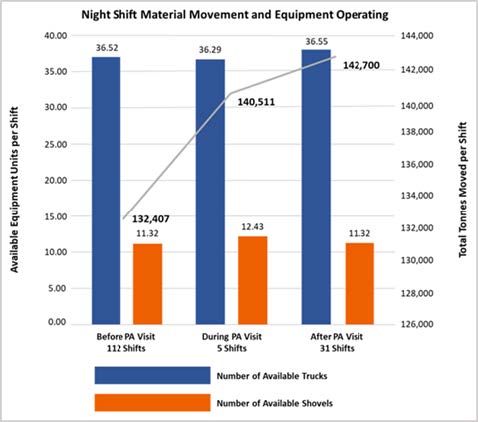

One month after the PA team worked with the dispatchers, Bear Run’s night-shift production rates and truck availability increased by 7.77%. This equates to nearly 10,300 additional tons of material moved per shift – an estimated monthly gain of $1.6 million USD, according to Eric Griffith, Lead Dispatcher at Bear Run.

The improvements shown in the graph can be directly attributed to the dispatcher coaching sessions and Bear Run’s willingness to alter a number of their operating practices based on the PA team’s recommendations.