Mining Optimization Series: Part 2

Achieving the connected mine

The first blog post in our Optimization series focused on the basics of mining optimization: what it is, what it isn’t, and why it’s important. We gave examples of real mines who have seen real improvements as a result of a focus on optimization.

In this post, we’ll take our discussion about optimization a step further, and explore some of the latest mining innovations that are helping organizations get closer to achieving the sought-after “connected mine.” By focusing on optimization, and leveraging the integrated capabilities of multiple technologies, mines everywhere can improve productivity across the mining value chain.

Integrating Fleet Management and Machine Guidance Systems

While machine guidance and fleet management systems (FMSs) have undoubtedly proven their ability to drive improvements in productivity and accuracy on their own, their capabilities and value can be increased dramatically when integrated together.

For example, mines wishing to manage and improve their material blending can leverage a robust FMS (such as our DISPATCH® system) in combination with a high-precision machine guidance system (such as out ProVision® system for loading equipment). The improved shovel accuracy afforded by the machine guidance system reliably ensures that the material loaded into trucks aligns with the mine plan, while the FMS ensures the correct routing of that material to appropriate stockpiles or crushers.

Mines that leverage the DISPATCH FMS also have the optional Blending and Dynamic Material Inventory Reporting modules at their disposal, which further optimize the material blend by:

- Automating blending at crushers

- Maximizing stockpile management and efficiency

- Reducing material re-handle

- Monitoring and tracking grades

- Tracking the amount of material at blast, stockpile, and dump locations

Implementing a high-precision machine guidance system for drills, which provides continuous navigation to help drill operators satisfy accurate hole patterns, depths, angles, and spacing, can further improve the reliability of the material being dug.

Real-world example:

A nickel mine in Brazil recently relied on the ProVision system for loading equipment, the DISPATCH FMS, and its optional Blending and Dynamic Material Inventory Reporting modules, to improve their material blending. As a result of the integrated technologies, the mine was able to reduce their ore dilution by more than 2%, representing a 1.1% increase in material grade output and an estimated $5.7M in additional revenue per year.

The ProVision system for drills can optimize material fragmentation and resource management by ensuring the right material is blasted, and with the appropriate explosives. This ensures that the mine is extracting the desired grade and material type, while improving digability for shovels at the dig face and minimizing stoppages at the crusher as a result of incorrect blends or improperly-fragmented material.

Integrating fleet management and machine guidance systems can also help with any reconciliation efforts that a mine must sometimes undertake to explain deviations from plan.

“With fleet management and machine guidance, we can now say, with a pretty strong level of confidence, that we moved X many hundreds of thousands of tonnes, from this location to this location,” explains Steven Peugh, Global Sales Manager for Modular Mining. “This confidence can help miners troubleshoot reasons they may not have moved as much ore as planned by streamlining and reducing the entire reconciliation process, allowing them to instead investigate their recovery rates, grades, and other factors that may have led to the deviation from plan.”

Connecting 3rd Party Mining Systems

We recently launched a series of APIs designed to enable the DISPATCH and ProVision systems to communicate bidirectionally with 3rd party systems, thereby enhancing functionality at both ends.

By exchanging data and consolidating it into one common language, the APIs can help mining organizations dramatically optimize their production, equipment uptime, efficiency, and more.

So far, we’ve developed APIs for:

Supervisory Control, via the Core API

The Core API exchanges data between the DISPATCH and/or ProVision systems and any supervisory and control system, such as Enterprise Resource Planning (ERP) systems like SAP.

The API enables immediate publication of production, time tracking (for time model usage), and dispatcher input event notifications, and allows for a complete feedback loop among external or downstream systems. It also increases modelling accuracy within third-party systems, thereby helping to improve plan compliance.

Sharing data between supervisory systems and production systems, in real time, enables the API to help operations optimize their overall productivity. But it’s not just about productivity – “Maintenance departments can also leverage the API to optimize their workflows,” explains Mark Webb, Global Solutions Manager at Modular Mining.

“Integrating DISPATCH and ERP data enables us to use business logic to determine what to do with a ‘down’ equipment status.” The API enables the sharing of such key information as equipment location at the time the unit was put into ‘down’ status, and the name of the operator who put the unit down, among many other datapoints.

“For a maintenance crew, a downed asset’s location isn’t always obvious,” says Webb. “Having the location information via the API helps maintenance crews optimize their workflows because they’re not having to track these units down. Likewise, knowing who the operator was at the time the unit was downed, and being able to talk to that operator – to identify any smells, sounds, unusual movements, or other details that occurred when the operator downed the unit – can help maintenance teams further their fault diagnostic efforts and get equipment back up and running much faster.”

Crusher Management, via the Crusher API

The Crusher API uses Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controller (PLC), and DISPATCH FMS data to optimize productivity by reducing queues and bottlenecks at the crusher.

The API provides real-time visibility into crusher status, performance, and feed rate, while automating advancements of crusher-related load and haul cycle states.

It enables the DISPATCH FMS to redirect trucks to stockpiles and mitigate the effects of unnecessary queuing at the crusher (such as fuel and time waste, and the potential for vehicle-to-vehicle interactions as a result of too many trucks squeezed into a confined area).

The API also enables the monitoring of bin levels in real time, reducing black belt losses by calling for ROM feed on demand.

“Black belt heavily impacts downstream systems,” says Webb. “With the Crusher API, we’re trying to get that ‘just in time’ requirement, so we eliminate queuing at the crusher while maintaining a constant feed.”

Aftermarket systems integration, via the Heavy Mobile Equipment (HME) Aftermarket API

The HME Aftermarket API layers information from the DISPATCH FMS with bolt-on solutions that are not part of the original manufacturer’s build, to create some decision-making logic about these solutions.

“One of the ways that operations can use this API is for identifying contaminated loads, from a tooth detection system,” says Webb. “Being able to automate the decision to reroute a truck that is suspected of carrying a contaminated load reduces risk to the crusher and potential downtime.”

Aftermarket solutions, such as a camera-based tooth detection system, fatigue management system, and proximity detection systems are excellent candidates for the HME Aftermarket API.

“Enabling the exchange of real-time information between aftermarket products and the DISPATCH system significantly reduces the lag for any potential intervention. Layering this information provides a deeper understanding and better decision logic, resulting in a safer, more efficient and productive operation,” Webb concludes.

Mine Planning, via the Machine Guidance API

The Machine Guidance API connects the ProVision system to a third-party mining application, enabling mines to bridge the gap between planning and execution, and optimizing their mining operation by enhancing the visibility between the field and mine planning department.

The API enables real-time updates to the mine planning software, rather than having to send huge chunks of data at the end of a shift or during a weekly update.

“Exporting a design out into the field is typically a manual, and, quite frankly, annoying, process to have to go through multiple times,” said Mark Webb. “It’s a laborious task, especially when it’s repeated numerous times. So what we’re trying to do with the API is create a much more seamless environment for the ProVision and Mine Planning systems to talk to each other.”

“This provides the planners with a direct correlation between what they’re delivering to the field, and what’s actually occurring in the field. We see a huge potential for the planning group to be able to use this to see what’s happening in the field,” continues Webb.

Payload Management, via the Payload System API

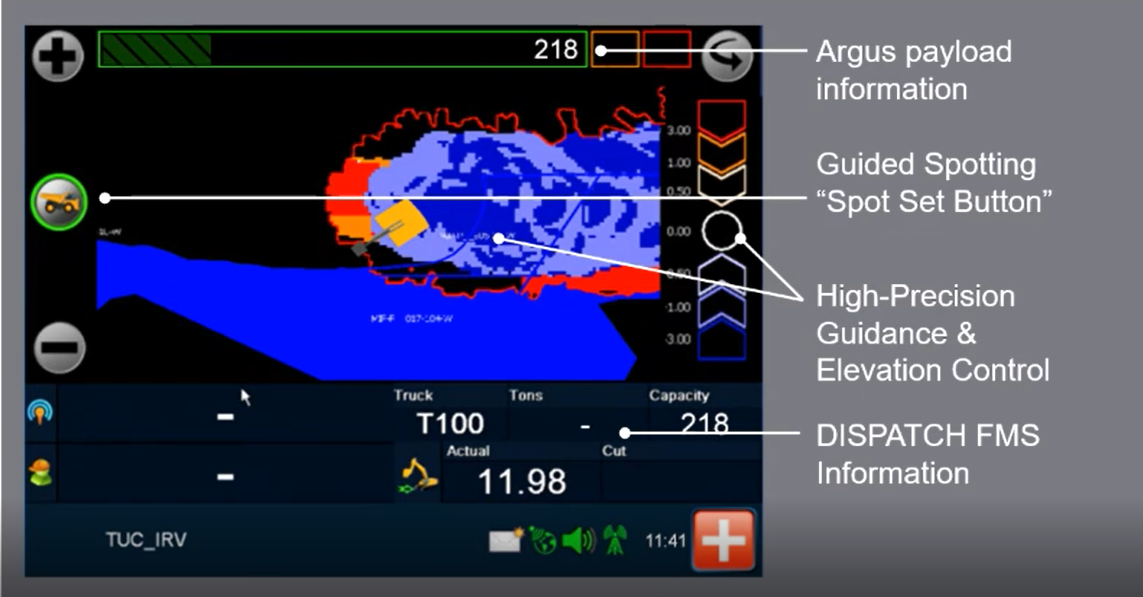

The Payload System API layers information between the ProVision and DISPATCH systems, and third-party shovel payload monitoring systems like the Argus system, to optimize payload.

“The goal with this API is to improve payload accuracy to narrow the bell curve and get as close as we can to the target payload – and then replicate that consistently,” explains Webb. The API consolidates inputs into the DISPATCH and ProVision systems, as well as truck and shovel payload data, and presents it all in a unified, single interface. “This allows us to centralize payload reporting, decrease instances of over- or under-loading trucks, and increase payload accuracy by reducing those outliers,” Webb explains.

The single display provides visual payload guidance directly on the ProVision mobile screen and eliminates the need for operators to interact with (or focus on) multiple screens, allowing them to instead focus on their task at hand:

The API also helps load and haul operations account for, and better manage, material carryback.

This shared information helps the shovel operator identify:

- That there’s already material in the back of the truck, and

- How much material there is, which they can then leverage to adjust loading practices accordingly.

“Carryback is an incredibly important part of loading a truck correctly to ensure we’re not overloading,” Mark Webb explains. “The API allows us to look at the carryback information at loading locations, as available from the OEMs of course, and then use the DISPATCH system to share that information with the ProVision machine guidance and Argus shovel payload systems.”

Mining optimization has always been the foundation of our customers’ success; it’s part of our company DNA and the cornerstone for the future of smarter, safer, more sustainable mining. The APIs help to refine mining optimization by enabling the real-time connection of technologies across the mining value chain. By connecting upstream and downstream processes, across all makes and models of equipment and technology, the APIs open the door to mine-wide optimization and interoperability.

SUBSCRIBE to our blog