Real-time Monitoring for Actionable Insights

You want to collect a wealth of data about your fleet’s health. But what will you do with it?

The MineCare® Maintenance Management system leverages intelligent computing capabilities to capture the right data at the right time. This predictive technology enables the step changes you need to digitally transform your maintenance process, helping to extend your equipment life and reduce total cost of ownership (TCO).

Capture the Right Data, at the Right Time, for the Right People. The MineCare solution drives more than just data – it drives action.

Achieve your Unstoppable Operation

The MineCare Maintenance Management system has enabled mines worldwide to:

What can the MineCare system do for you?

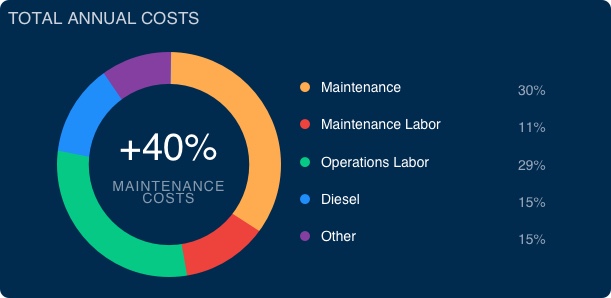

Maintenance accounts for a large portion of your overall operating costs; if you’re an average-sized operation, approximately 40% of your costs are probably maintenance-related.

These costs are typically some of the most controllable, however. By approaching maintenance proactively, rather than reactively (“run it until it breaks”), you can dramatically minimize your maintenance costs while maximizing your output.

MineCare System – Key Features & Benefits

Did You Know?

The MineCare solution actively monitors more than 5,500 units.

Get even more value from your MineCare System

RemoteCare

Off-site Monitoring

Consulting Solutions | Condition-Based Monitoring

Teams of highly-trained Modular Mining specialists remotely monitor and manage the real-time telemetry data generated by your entire fleet.

- Reduce unscheduled downtime

- Increase equipment reliability

- Identify best practices at benchmark sites that can be applied enterprise-wide

- Reduce operational and maintenance costs

"Thanks to RemoteCare’s proactive management of critical alerts, we have been able to optimize monitoring for our entire truck fleet, both Komatsu and CAT, by providing the right information to the right people 24 hours a day."

- RemoteCare customer in South America

Performance Assurance

Consulting Solutions | Customized Consulting

A dedicated team of Modular specialists collaborates with your mine personnel to establish mutually-defined goals and milestones, delivering even more value from your MineCare system.

- Enhance equipment productivity

- Reduce truck queue times

- Improve net production through shorter shift change duration

- Reduce equipment maintenance costs

"In the Performance Assurance area, they send a wide variety of professionals to the site to help deal with the different problems we have. We got some solutions to some of the problems we had and it was a great win for us. "

- IntelliMine Client in North America

MinePlan Compliance

Consulting Solutions | Customized Consulting

Our technology-based consulting approach helps you create synergy between departments, processes, and systems, thus increasing your ability to consistently execute according to plan.

- Facilitate the cultural shift your personnel may need to accept and internalize changes to operating procedures and best practices

- Improve efficiency, performance, and process control

"They really helped us find the opportunities to increase the overall performance of the mine - certainly provides added value. It added value to our operation."

- Mine Plan Compliance Client in North America

Featured Resources

Sustain Your Value: The Big Picture

Leverage Modular Mining’s full solutions suite to truly maximize your value, sustain your improvements, and grow over time. Each system and service builds upon another, providing more value and process improvements than you can derive from just a singular technology.

Without Modular Mining Solutions

With Deployment Services

With Customer Care Package

With Value-add Services