North American coal mine increases production by 6.5% with Argus Payload

Challenge

One of the largest coal mines in the world, producing morethan 80 million tons of thermal coal each year operates sought to optimize their load and haul operations on their fleet of overburden shovels after payload performance had plummeted with only 40% of loads falling within the acceptable payload range. This was impacted by operator performance issues, ineffective payload management tools and costly delays in payload feedback to operators.

The mine operates with four P&H4100 overburden shovels and a mixed haulage fleet of Liebherr T282s, Komatsu 960sand Komatsu 930and wanted to optimize their load and haul operations by improving operator performance, truck compliance and production while reducing costs.

LOCATION

Wyoming, USA

GOAL

Improve payload compliance

RESULTS

The mine increased production by 6.5%

Solution

Argus E, Modular Mining’spayload management system for electric shovels provides a complete, integrated payload management solution. Providing real-time feedback on operator performance, Argus enables mines to reduce truck payload variability to maximize haul fleet productivity and shovel output.

Deployment

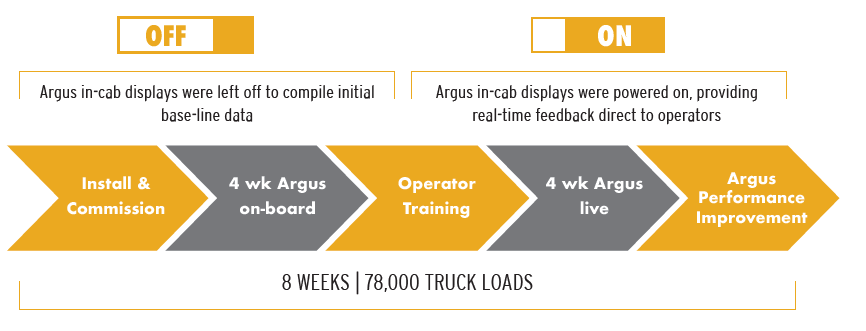

This North American coal mine deployed Argus E across its fleet of four overburden electric shovels and within four weeks, the site saw a significant improvement in operator performance and direct benefit in productivity, efficiency and haul fleet optimization. In an eight-week study period, Argus collected data across 78,000 truckloads. Argus’ intuitive, in-cab operator display was switched off for the first four weeks of the study. This eliminated as many variables as possible to ensure an accurate comparison of results with and without Argus’ real-time feedback.

Results

Argus increased the number of compliant trucks while reducing the number of underloads (<95%) and major overloads (>120%).

• 1.2% reduction in major overloads (from 1.6% to 0.4%)

• 35% increase in compliant trucks (from 39% to 74% of total loads)

• 35% reduction in underloads (from 54% to 19% of total loads)

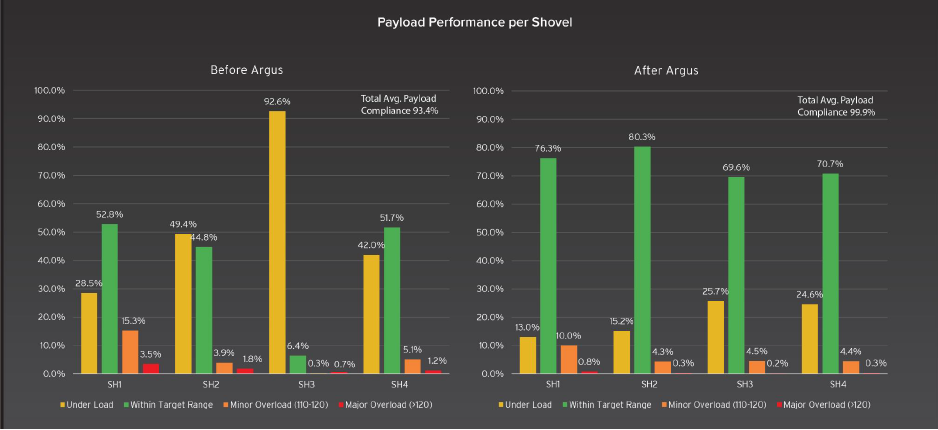

Payload Performance | Per Shovels

Argus reduced operator variability with consistent operator performance improvements measured across all four shovels.

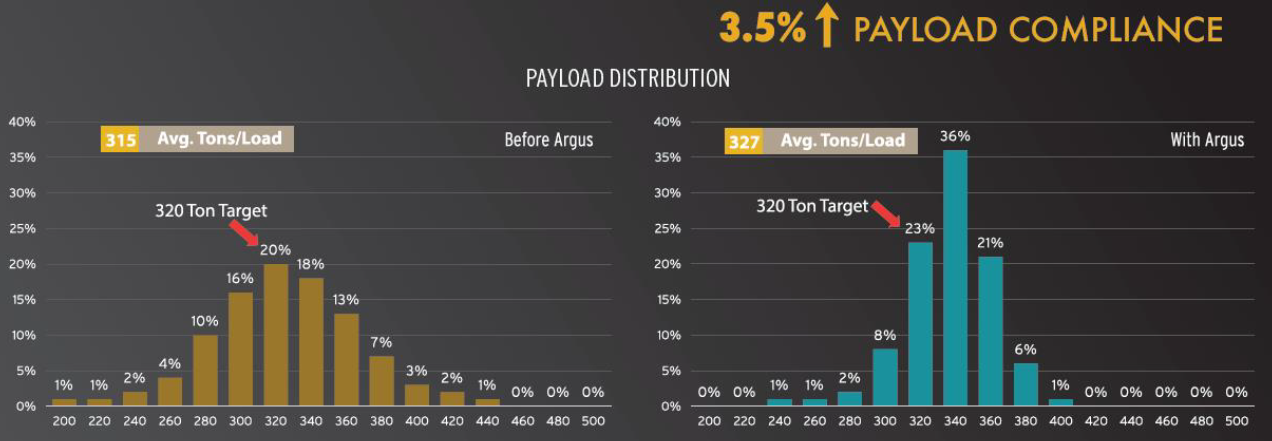

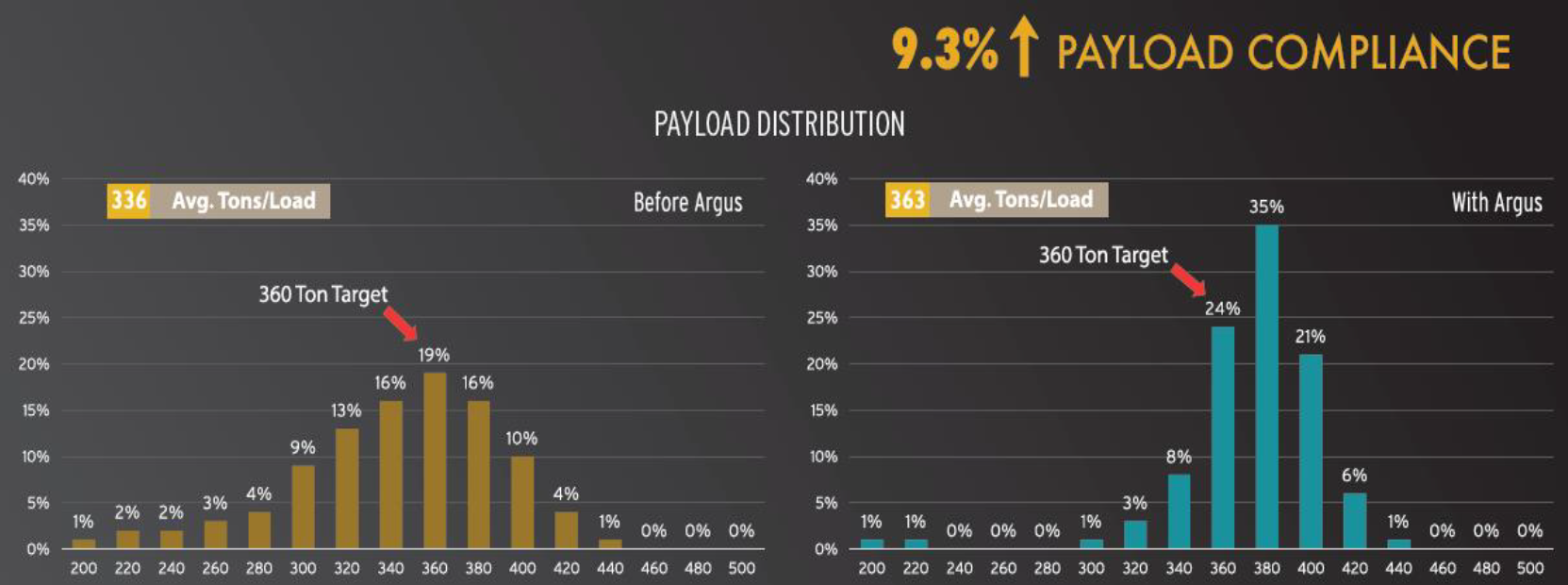

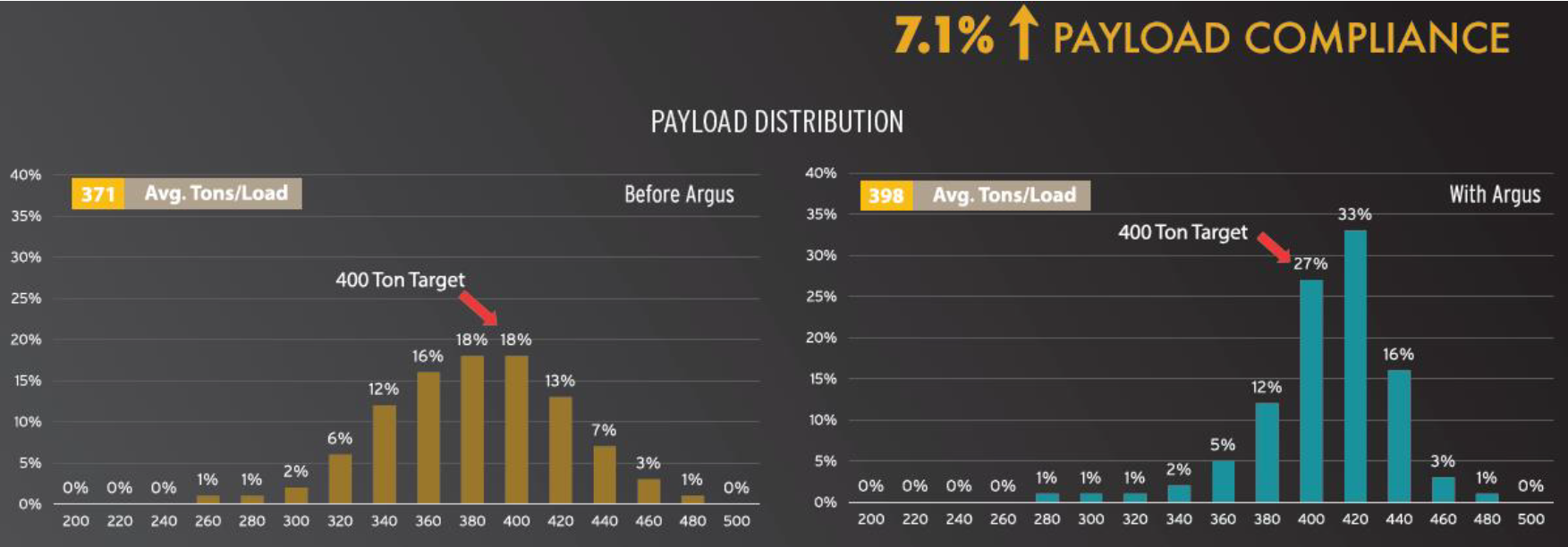

Payload Distribution and Compliance

Argus reduced payload variability across the customer’s mixed truck fleet to tighten payload distribution and improve payload compliance by 6.5% (from 93.4% to 99.9%).

Komatsu 930s

Komatsu 960s

Liebherr T282s

Outcome

Shovel operator performance improved after four weeks of Argus on board, delivering impressive advantages in productivity and haul fleet efficiency. The site increased their average truck loads per hour and moved more tons each day, resulting in a production increase equivalent to gaining two entire trucks. If the site removed two of its existing trucks, they would maintain current production output while saving $3 million each year, based on current commodity pricing.