Modular Mining Services Dispatcher Coaching

Challenge

After years of running the DISPATCH® FMS in hands-off, locked-mode, the mine made the decision to utilize live dispatchers and leverage the system’s optimization capabilities.

However, limited understanding of the DISPATCH system’s features and functionality, as well as the absence of experienced dispatch personnel, presented a number of challenges in the mine’s ability to make the transition.

LOCATION

Chile

OBJECTIVE

Through coaching and training, educate novice dispatchers on the capabilities and correct use of the DISPATCH Fleet Management System (FMS), empowering them to make confident and knowledgeable operational decisions.

OUTCOME

During and after DISPATCH system coaching, the mine saw consistent increases in production totaling (on average) 3,533 additional tons moved per shift vs. baseline results.

Solution

Modular Mining Services provided classroom “theory” training and in-seat coaching to newly appointed dispatchers and their assistants. Through in-depth study of DISPATCH system concepts, applications, and utilities; and practical, hands-on experience, the new dispatchers gained the confidence and sense of empowerment needed to take control of their shifts.

Background

When the large open-pit copper mine implemented the DISPATCH system in the early 2000s, it was configured for “dispatcher-less” operation. In this mode, the system utilized the mine’s fixed truck-to- shovel pairings and pre-defined haulage routes. Few, if any, adjustments were made to the initial configuration despite ongoing changes in the mine’s working environment.

Over time, the mine came to realize that live dispatchers in the control room were essential to maximizing the production process. As a first step, individuals were chosen from operator crews to step into the dispatcher role. Unfortunately, because the selected personnel received only rudimentary DISPATCH system training, the novice dispatchers lacked both the confidence to make critical decisions and the knowledge to fully utilize the FMS to optimize the production process.

Methodology

By implementing a combination of classroom training and directed coaching, Modular Mining Services provided new dispatchers with valuable exposure to the features, functionally, and benefits of the DISPATCH system. Primary topics covered included:

- DISPATCH system Introduction

- PitGraphics

- HaulRoute™

- Interruption Recovery

- Exceptions Handling

- Modular’s proprietary DISPATCH optimization algorithm

The dispatchers also gained insight into the areas of Shift Start, Optimization strategies, Locked vs. Dynamic Assignments, Proportional Feed, and LP Configuration. By the end of the training and coaching phases, the dispatchers walked away with extensive theoretical and practical product and task knowledge, leaving them better prepared to fulfill their new duties.

Results

In addition to providing dispatcher training, Modular Mining Services helped the mine calibrate its DISPATCH system settings to ensure proper LP configuration. As a result, the mine experienced a substantial increase in production volume and cost benefits.

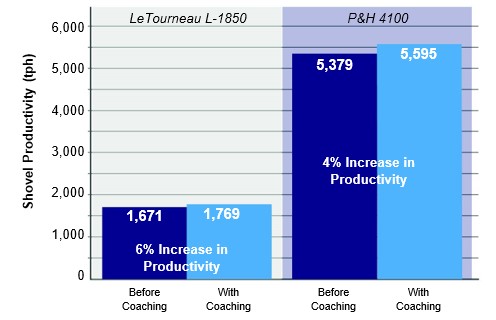

Following dispatcher coaching and training, the mine was able to effectively utilize the DISPATCH FMS’s optimization capabilities. As a result, shovel productivity showed an overall increase of 10%.

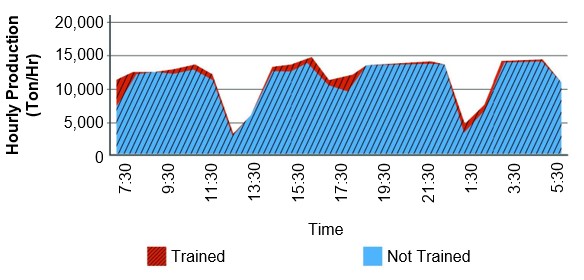

Hourly production rates (tons per hour) increased consistently for shifts during which dispatcher coaching was in progress.

Productivity Increase with Dispatcher Coaching

Mine Productivity (Ton/Hr)

Conclusion

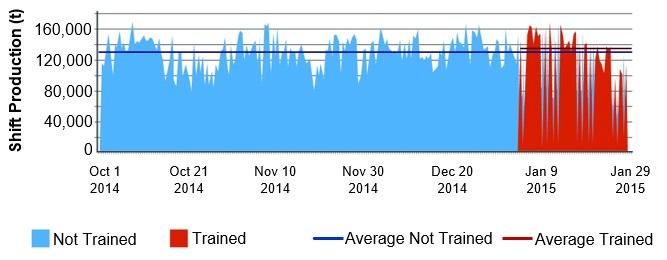

Before Modular Mining Services conducted system training and dispatcher coaching, the mine operated with 70% its trucks locked to specific shovels. In addition, the general lack of understanding of the DISPATCH system’s optimization algorithm and optimization capabilities led to frequent underachievement of the mine’s planned goal of moving 120 – 130 Kilotons (Kt) of material per shift.

During and after training and coaching, the mine was able to optimize its haulage cycle, which led to 100% percent of shifts running with trucks in unlocked mode. In doing so, the mine achieved or exceeded the targets set forth in the mine plan; in some instances moving as much as 150 Kt per shift.

On average, shifts in which dispatchers received coaching showed an increase of 3,533 tons (t) of material moved per shift.

Productivity per Shift

(October 2014 – January 2015)

Based on then-current costs and operational conditions, calculations revealed that 3,533 additional tons of material moved per shift represented a monthly cost benefit for the mine of $450,000 USD.

| Item | Unit | Value |

|---|---|---|

| Tonnage Increase per Day | tpd | 7,067 |

| W/O Stripping Ratio | # | 3.66 |

| Ore | tpd | 1,517 |

| Waste | tpd | 5,550 |

| Average Cu Grade | % | .74 |

| Mine Cost | USD / t mov | $2.5 |

| Plant Cost | USD / t proc | $8 |

| TC/RC | USD / lb | $.52 |

| Price Cu | USD / lb | $2.65 |

| Cu Metallurgical Recovery | % | 85 |

| Cu Content | lb | 21,007 |

| Item | Unit | Value |

|---|---|---|

| Mine Cost | USD / day | $17,668 |

| Plant Cost | USD / day | $12,137 |

| TC/RC | USD day | $10,881 |

| Income | USD / day | $55,668 |

| Profit | USD / day | $14,981 |

| Monthly Profit | USD / month | $449,424 |