Modular Mining’s Performance Assurance team helps African coal mine increase loading efficiency by 10% through real-time payload monitoring

A large coal mine in South Africa installed Modular Mining’s DISPATCH® Fleet Management System (FMS) in 2014 to optimize their haulage operations, replacing an incumbent system. Today, the mine also leverages the ProVision® Machine Guidance system on their fleet of dozers and drills to improve their precision to plans.

LOCATION

South Africa

OBJECTIVE

Reduce truck under-loading and increase production

OUTCOME

10% increase in truck loading efficiency

Challenge

The mine manually tracked their payload volume by correlating their specific truck capacities with the number of loads hauled by each, throughout a shift. As with most manual processes, this created issues around data accuracy and consistency, making it difficult to proactively monitor and manage their payload efficiencies with higher levels of confidence.

During a recent customer visit to the mine, Modular Mining’s Performance Assurance (PA) team compared their surveyed payload volume to the actual production volume reported by the DISPATCH FMS and found that the reported volumes varied significantly. As a result, the site’s trucks were being underloaded by an average of 13%, which limited the operation’s productivity.

Methodology

After identifying the payload discrepancy, the PA team worked with the mine to implement the optional Payload module into their DISPATCH FMS. The module captures real-time payload information from the VIMS systems within the mine’s fleet of Caterpillar trucks. The module then transmits this data to loading equipment operators in real time, increasing their visibility and awareness of their actual payload volume, and can also be stored for comparison against historical production records for detailed analysis and reporting. The PA team worked directly with the mine’s technical team and the OEM support team to collect data for improved calibration, and to identify potential equipment issues.

With the Payload module enabled, the PA team silently tracked the mine’s true payload for roughly 6 weeks to generate a reliable baseline. Following the baseline period, and leveraging data from the VIMS interface, the PA team then worked with the mine and its Business Improvement (BI) team to develop operator-based scorecards, providing each operator with visibility into their own loading efficiency. This increased visibility provided insights to specific operator performance, identifying additional training opportunities for operators that needed it.

The Performance Assurance Advantage

Modular Mining’s service and support offerings reinforce the company’s commitment to ensuring that every customer realizes maximum value from their Modular Mining technology investment.

During each on-site Performance Assurance engagement, a dedicated team collaborates with your mine personnel across multiple levels to develop tailored, flexible, and proactive solutions.

Working together, we establish mutually-defined goals and milestones, and create and track quantifiable key performance indicators (KPIs).

Participating mines have seen numerous benefits, including:

Enhanced truck productivity

Enhanced truck productivity

Reduced truck queue times

Reduced truck queue times

Improved net production through shorter shift change duration

Improved net production through shorter shift change duration

Lowered equipment maintenance costs

Lowered equipment maintenance costs

Results

During the 6-month period following the baseline study, the PA team focused on Assisted Operations training for the mine’s dispatchers and supervisors. Biweekly reviews with key stakeholders identified additional opportunities for calibration and loading efficiency improvements. At the end of the 6-month period, the variance between the mine’s target and actual payloads diminished significantly.

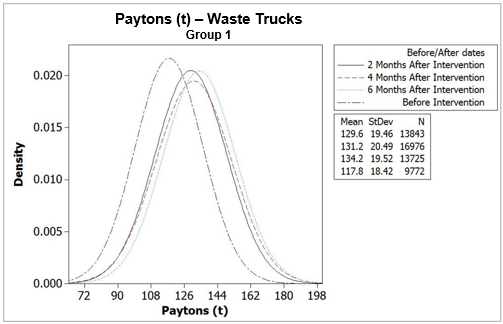

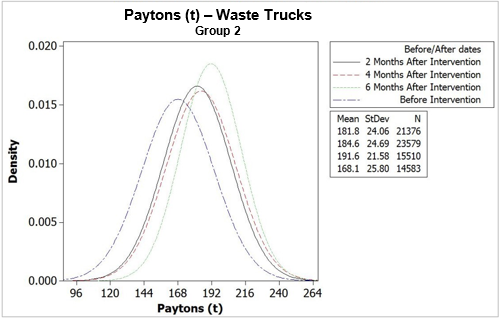

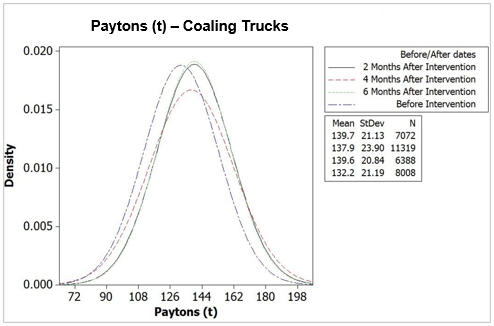

After implementing and calibrating the VIMS interface, the mine has increased their truck loading efficiencies by 10%. The greatest improvement can be seen in the mine’s two groups of waste trucks, for which payload increased by 15% and 14%, respectively, as shown in Figures 1 and 2. The mine’s Coaling Trucks also improved by approximately 5.6%, as seen in Figure 3.

“The measurement of elements of the equipment performance through the Modular [Mining] FMS is key to tracking and sustainability of the initiatives and ideas. Working together, the [PA] team has been instrumental in customizing the details we measure, to the requirements of the line management, as well as the Business Improvement software initiatives.”

– Business Improvement (BI) Manager

Conclusion

Through collaboration with Modular Mining’s PA team, site personnel, and the OEM support team, the mine’s total production has improved significantly. Achieving these gains required the mine to adopt a new process for tracking their payload volume, as well as a new KPI by which to determine individual operator success. By leveraging the calibrated, real-time data from the VIMS interface via the DISPATCH FMS Payload module, the mine improved their loading efficiency by more than 10%, which contributed to an increase in the mine’s overall production and provided more reliable payload data, for continuous improvement opportunities.