Modular Mining’s Performance Assurance team helps an Australian coal operation put the brakes on speed-related incidents

Modular Mining’s Performance Assurance (PA) team commenced work on a new project in November 2017, at an open cut coal mine in New South Wales. Throughout the engagement, part of an ongoing PA relationship, the team collaborated with mine personnel to address one or more aspects of their continuous improvement plan.

As with many surface mines in Australia, the traffic control methods used along haulage routes differ from those used on public roadways. For example, instead of STOP or GIVE WAY signs posted at intersections as one might encounter on a standard thoroughfare, the site manages in-pit traffic flow through a hierarchical system based on vehicle size and type.

LOCATION

Australia

GOAL

Reduce intersection incidents resulting from speeding

RESULTS

Dramatic reduction in speed-related incidents at intersections

The Priority Pit Traffic Rules not only reduce congestion and bottlenecks for increased productivity; they also improve safety because the right-of-way is given to vehicles approaching from the left, where visibility is best for haul trucks. Additionally, one of the site’s best practices dictates that drivers must slow their speed to 40km/h at the mine’s busiest intersections, as indicated by colored markers.

PA evaluated the mine’s haulage efficiency by analyzing speed variations among old and new trucks in the fleet during a visit in June of 2018. While observing the haulage routes, PA discovered and reported that operators routinely traveled through high-traffic intersections at speeds above the mine’s prescribed limit. Concerned with the potential safety risks, mine personnel requested that PA turn their attention to investigating and resolving the issue.

Problem

Investigation results from early June through early July revealed that drivers routinely proceeded through intersections at speeds above the defined limit. Upon being made aware of the issue, the mine asked PA to narrow the scope of their analysis to the seven intersections governed by the 40km/h restriction.

Not long after PA began its targeted research, a serious truck-on-truck accident occurred at the site. To help in the reconstruction of events leading up to the incident, PA extracted GPS location data from the DISPATCH® Fleet Management System (FMS) database. Mine personnel and investigators used the Modular Mining-provided data as a tool in identifying the circumstances of the accident, later determined to have been the result of driver fatigue.

Solution

Following the accident, the mine held safety briefings with the operators and erected reminder signage at speed-restricted intersections. The mine also took steps to further improve driver intersection visibility by ensuring that all crossroads were at 90-degree angles (no obliques), windrows were at the correct height and placement, and all signage and delineators were well maintained and clear of dirt and debris.

Results

When the PA team returned to the site for a follow-up engagement, they reported upon the data collected and analyzed during the intersection speed investigation. The improvements described below, and illustrated in Figures 1 – 3, are directly attributable to the mine’s adoption and execution of the PA team’s recommendations for change:

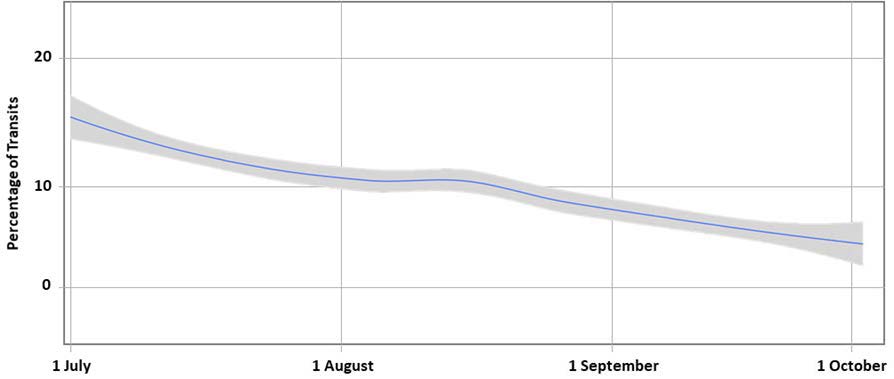

- Speed-related incidents at all seven 40km/h-restricted intersections dropped from 15% to 4%, for a 73% overall improvement in compliance (see Figure 1)

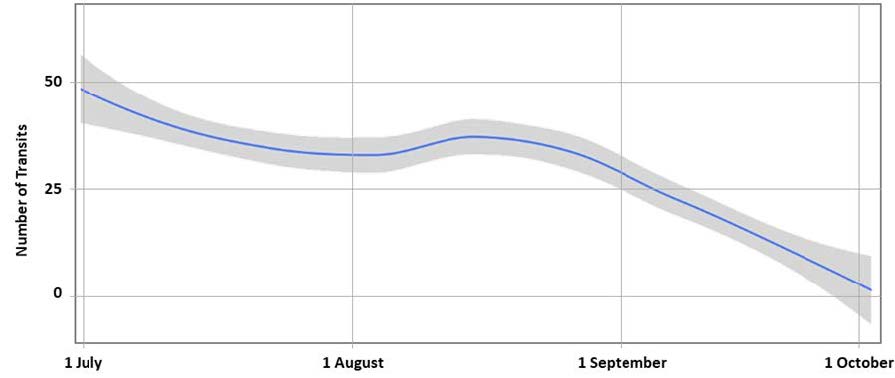

- Dramatic decline of nearly 100% in the number of speed-related events at an intersection where close to 50% of the through-traffic previously exceeded the 40km/h restriction (speeding incidents at all seven 40km/h-restricted intersections dropped from 15% to 4%, for a 73% overall improvement in compliance (see Figure 2))

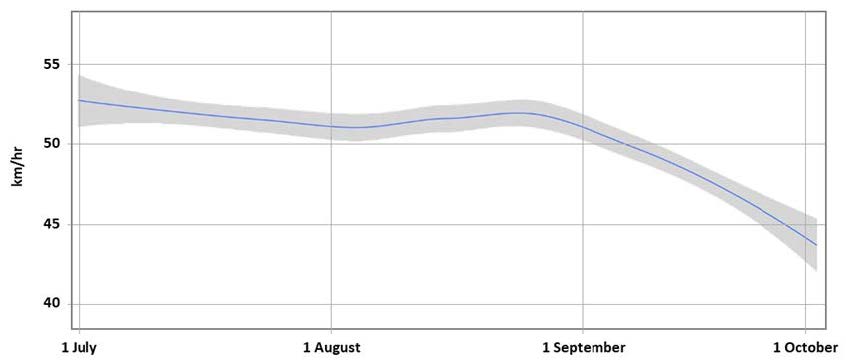

- More than 10km/h reduction in speeding events at some speed-restricted intersections (single intersection shown) where the average travel speed dropped dramatically − from 53km/h to 43km/h (see Figure 3)

Figure 1. Reduction in the percentage of speed-related incidents at all speed-restricted intersections

Figure 2. Reduction in the number of speed-related incidents at a specific speed-restricted intersection

Figure 3. Reduction in the number of speed-related incidents of more than 10km/h at a specific speed-restricted intersection

To further increase safety risk mitigation, the mine elected to add the DISPATCH Speed Management module, which measures equipment velocity as it travels through GPS-monitored zones, to its FMS configuration. When used in conjunction with the FastFeedback module (already installed at the mine), supervisors and operators will receive simultaneous, real-time speed violation notifications, facilitating heightened driver awareness, immediate corrective action, and ongoing behavior modification.

Conclusion

With the help of the Modular Mining PA team, the mine was able to identify a previously-undetected issue with potential safety risk implications. The mine was able to resolve the problem by utilizing functionality within its existing DISPATCH FMS and by adding real-time speed management capability to improve procedural compliance in the future.